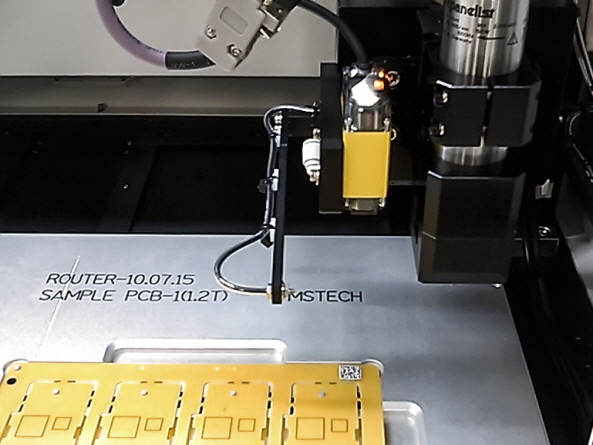

MSTECH

Home Products > PCB Depaneling Router

Product

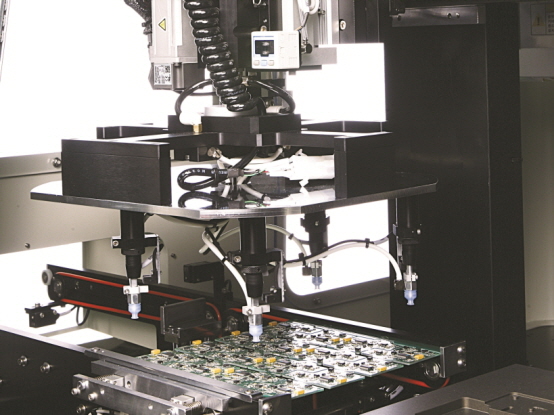

iDPL-D (Dual) Dual In-Line Router

Features

- The Fastest & No.1 Router in the World

- Dual Station Concept Router for the Fastest & Mixed Production

- Independently Dual Transfer for Minimizing Idle Time

- High Efficiency Dust Collecting System for 0% Remaining Dust

- Quick & Easy Programming with Camera & MPG/Jog

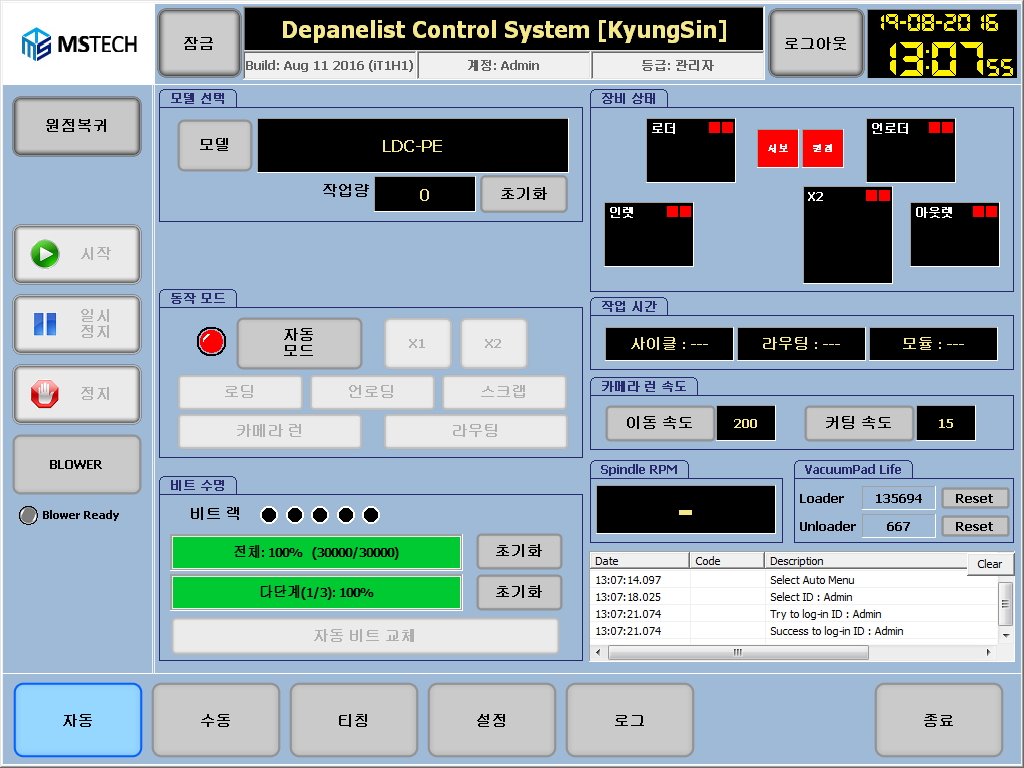

- User Friendly GUI based on IPC& Touch LCD

- Compact Design

Options

- Vision System

- Barcode Interlock & MES Interface

- Visual Data Log System (Visual Recorder)

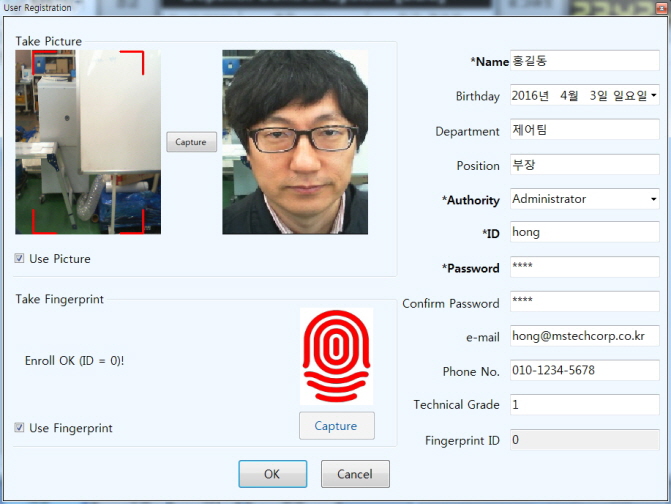

- ID Verification with Fingerprint

Features

-

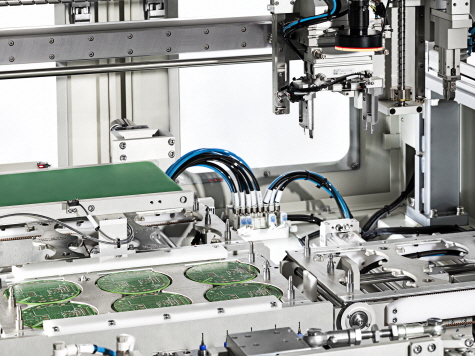

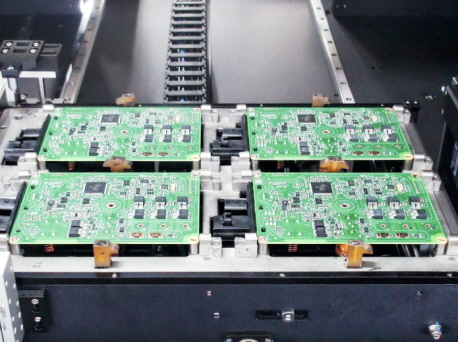

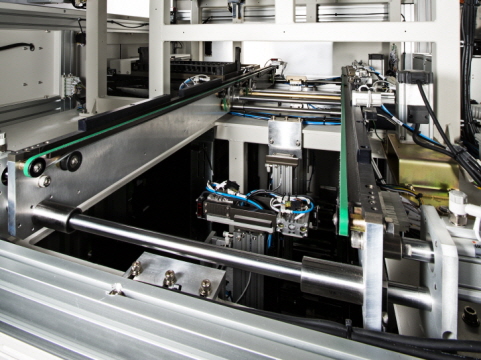

- Dual Station

- For dual lane product line.

It is able to be implemented double performance and produce mix products with two working station as front & back.

-

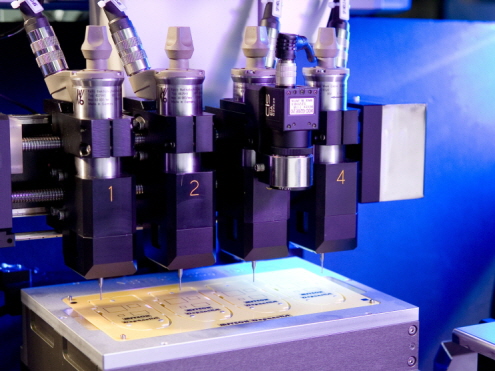

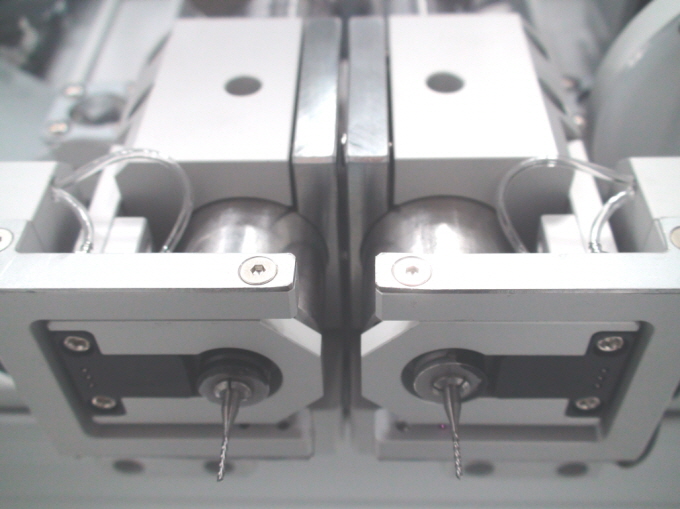

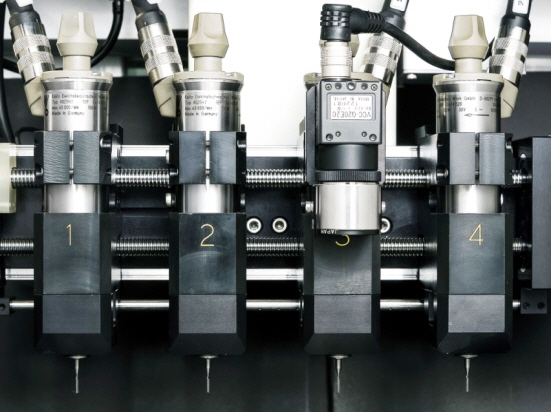

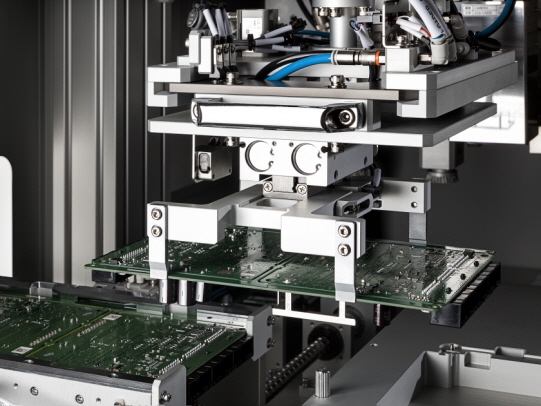

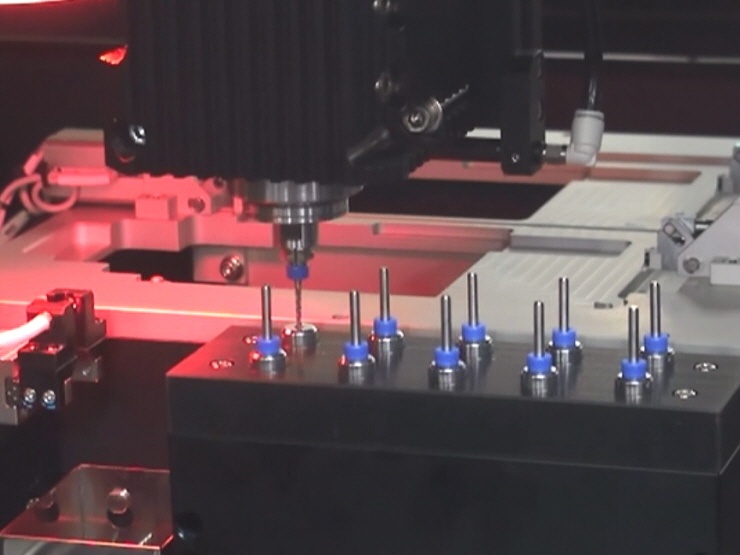

- Automatic Width Adjustment for Multi-Spindles

- It is able to be installed 2~4 spindles, and be accurate and convenient operating by automatic width adjustment.

-

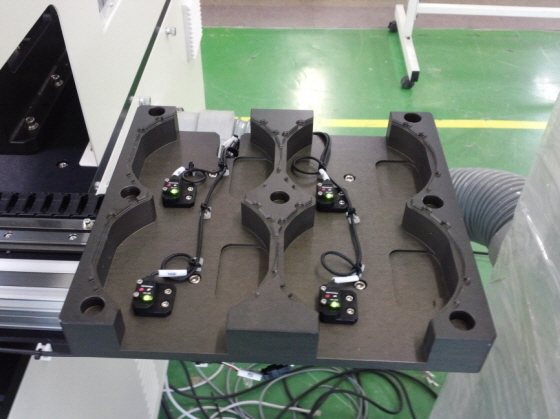

- Magneto Vacuum Type Loader/Unloader

- It is able to be model change quickly & easily by applied magneto vacuum type loader & unloader port.

-

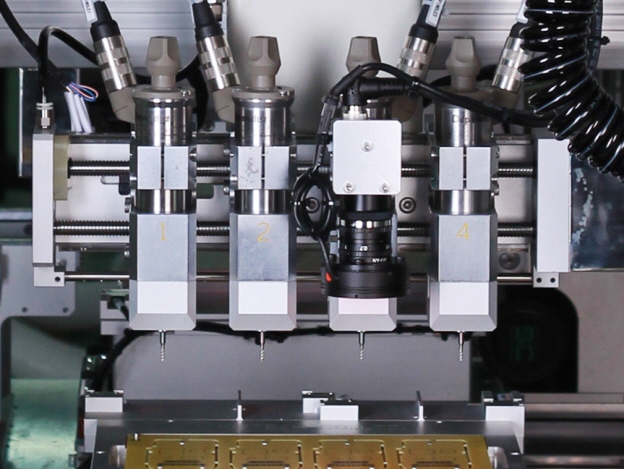

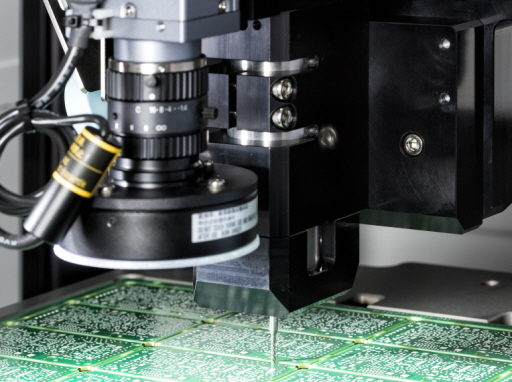

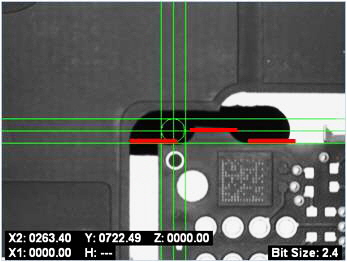

- Camera Teaching

- It is available teaching accurately & easily to use camera

-

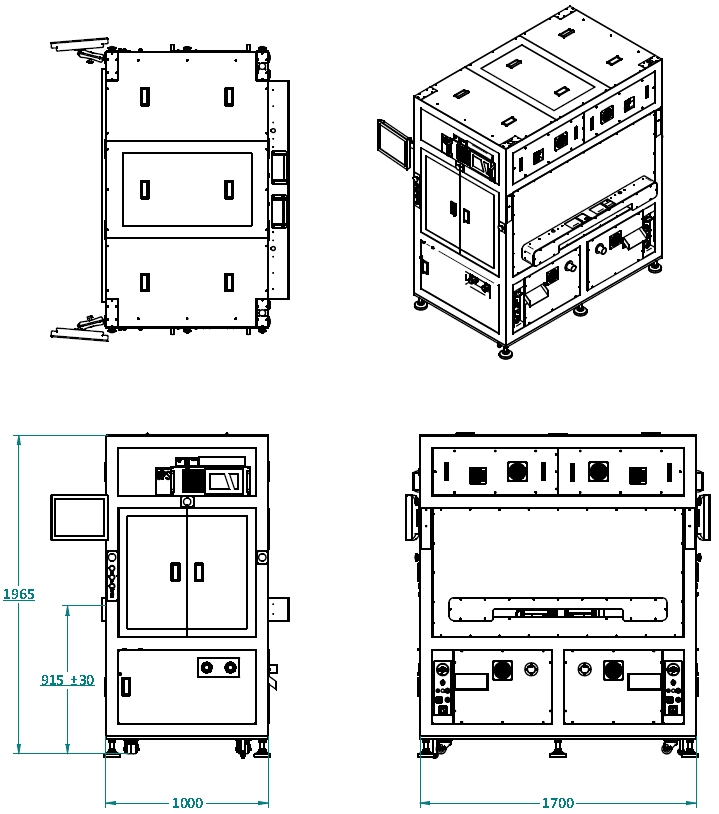

- Compact Design

- It is the most compact design for securing customer space

-

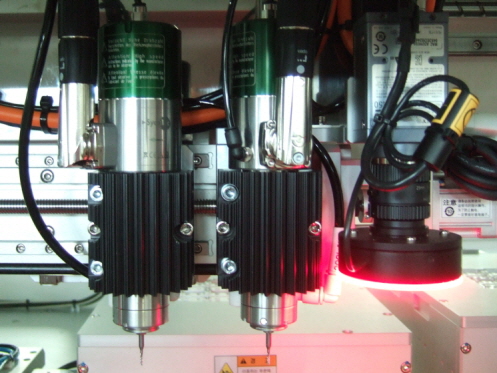

- Bit Broken & Slip Down Detection

- Bit detection sensor is standard installation for sounded alarm when bit broken & slip down.

-

- Ionizer

- It is standard installation for protected PCB and efficient removing dust(area ionizing type)

-

- Aligner (InLet Conveyor)

- Aligner + Inlet conveyor is integrated system, and able to receive the PCB with any position by variable aligner in depending on position of conveyor of front equipment.

-

- Total 16 Axis Servo System

- It is able to do auto controlling for all inside process by 8 axis on each stations.

-

- Loader Rotating

- Loader is rotated 90 or 180 degree by model for fixing PCB on the jig or cutting area.

-

- Multi-Bit Function & Life Time Management

- It is using multi-bit by 2~3 level for reducing consumable cost of customer and sounding alarm when bit is on each level by life time management.

-

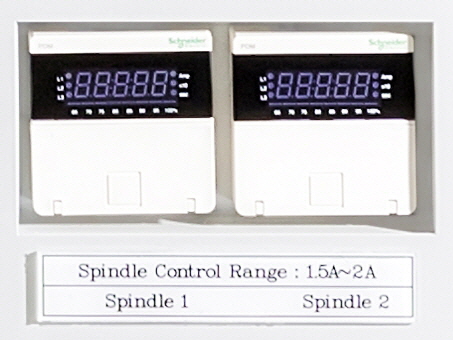

- Spindle Mate

- Inner EOCR is standard installation for protecting PCB damage as from cutting overload condition by detecting current of spindle motor with real time.

-

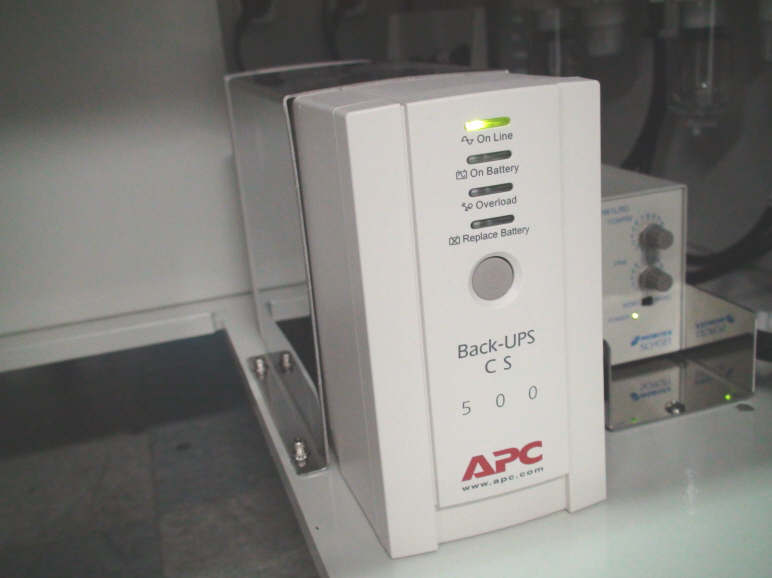

- UPS

- It is as installed as standard, and protecting data and equipment from line shout down.

(IPC covering capacity)

Options

-

- Barcode Interlock & MES

- It is used vision system or scanner to read the 1D/2D barcode for MES function with costumer's network

-

- Pass/Fail PCB Separation

- It is separating and releasing the fail PCB by NG conveyor, after getting data of NG PCB from front equipment by MES.

-

- Vision System

- It is able to detect different model and loading fail, and available fiducial checking.

-

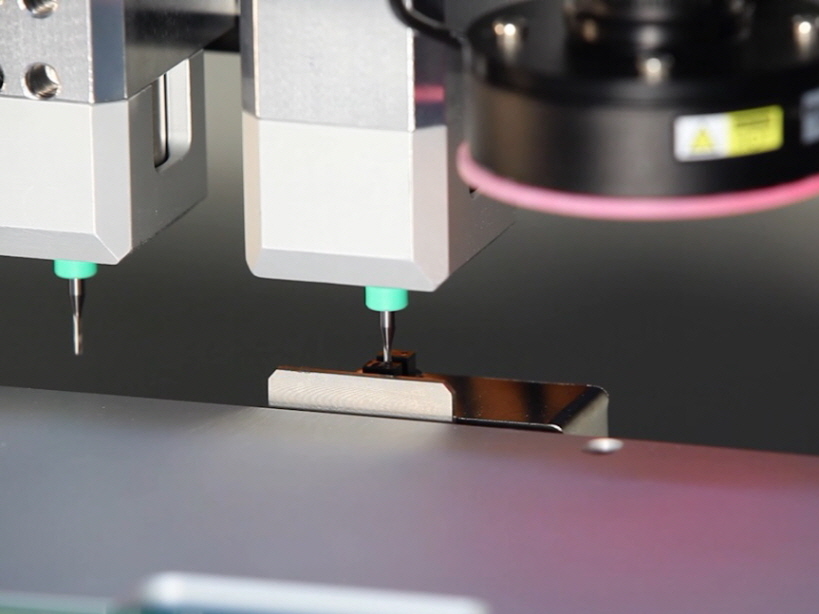

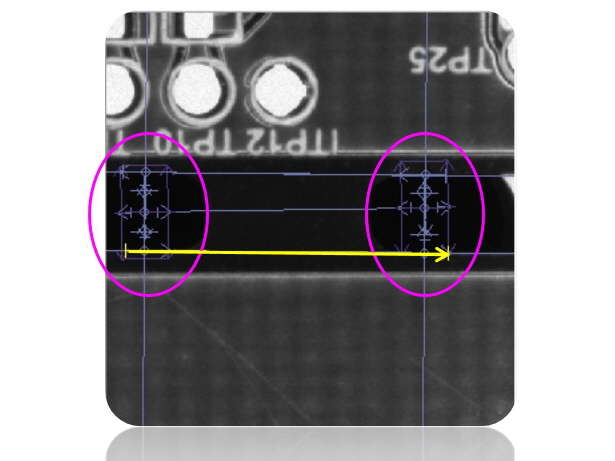

- Edge Detection Function

- As powerful vision system function, the both sides PCB edges beside a cutting tab are detected and compensate cutting position by tolerance of boards.

-

- ID Verification with Fingerprint

- It is available to be high security user management and easy logging by registered and appreciated user fingerprint.

-

- Dimensional Inspection

- It is inspecting cutting measure & burr after cutting, and able to implement additional cutting.

-

- Real-Time Spindle RPM Monitoring

- It is protected PCB with sounding alarm when spindle PRM is declining by detecting it in real time.

-

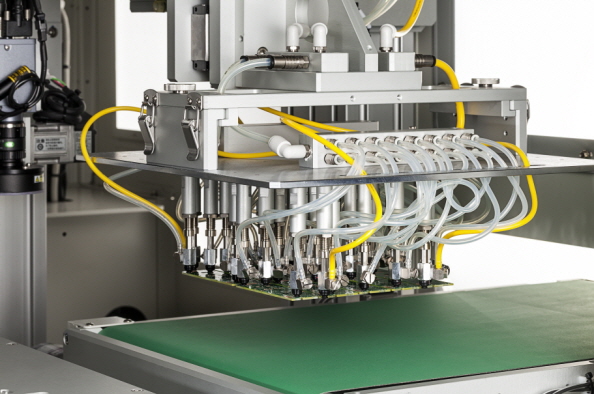

- Auto Width Adjustment for Multi-Spindle(AWA)

- It is able to install 3~5 spindles in depending PCB array. Each spindle is able to do auto width adjustment(AWA)

(Patent)

-

- Auto Tray Function

- It is loaded PCB after cutting it to tray or slot box by automatically, also auto changing and stacking tray or slot box when PCB is full in there.

-

- Pallet Transporting System

- After cutting PCB, it is released seated on the pallet from costumer.

-

- Shuttle Jig Outlet

- It is releasing PCB by seated on the shuttle jig for automation of next equipment.

-

- Gripper Unloader

- If there is restriction of unloading with heavy PCB or high component, it is able to use gripper type of unloader.

-

- 500W Spindle

- It is implemented more powerful performance by high capacity spindle(500W)

-

- Auto Tool Changing System(ATC)

- When life of bit is almost done or it is broken, it is changed the bit automatically. (Available with 4033 and 4041 spindle only)

-

- Auto Conveyer Width Adjustment

- It is saved model changing time by using motor to save the parameters of width pitch.

-

- Visual Data Log System (Visual Recorder)

- It is able to check phenomenon & cause by video recoding & saving inside of equipment when issue is happened during it is working.

-

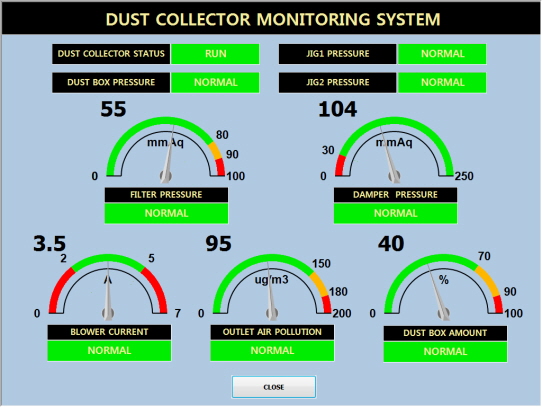

- Real-Time Self-Diagnosis Dust Collector

- It is able to do self-diagnosis about pressure, damage & pollution level inside dust collector and sound alarm to router(patent-pending)

-

- Filter+Cyclone Complex Dust Collector

- It is able to use filter semi-permanently with applied cyclone, and install plastic bag.

-

- Easy Handling Dust Collector

- It is able to use the plastic bag for disposing dust cleanly & easily.

Specifications(Standard)

Layout

Video