MSTECH

Home Products > PCB Depaneling Router

Product

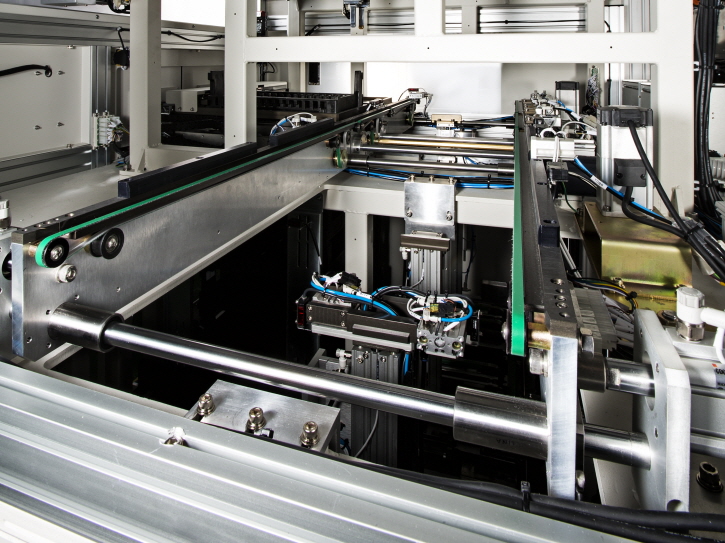

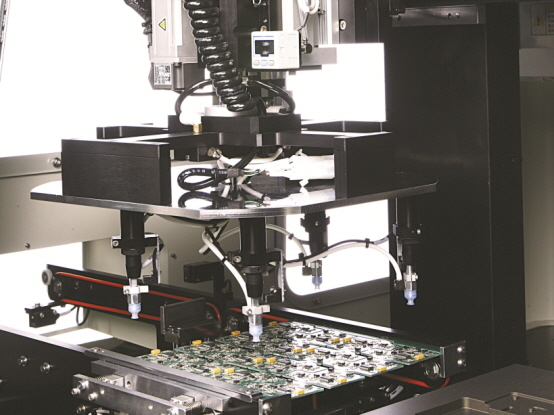

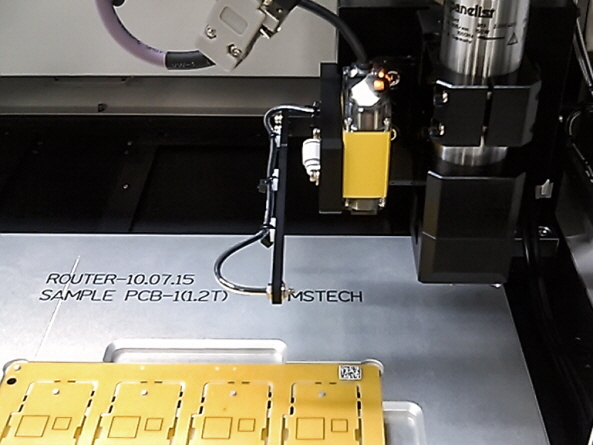

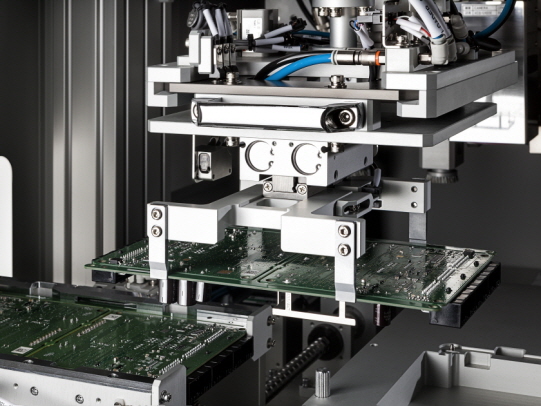

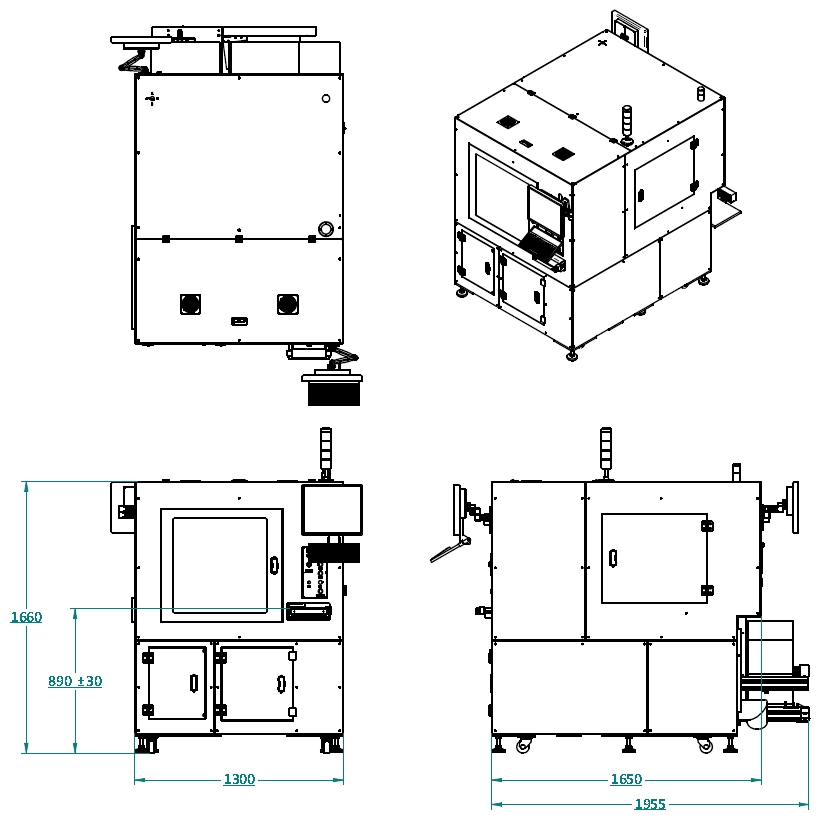

iDPL-ST (Single Tray) Ultra High Speed In-Line Router with Auto Tray System

Features

- Auto Loading System(Tray)

- Ultra High Speed Z Axis Up & Down

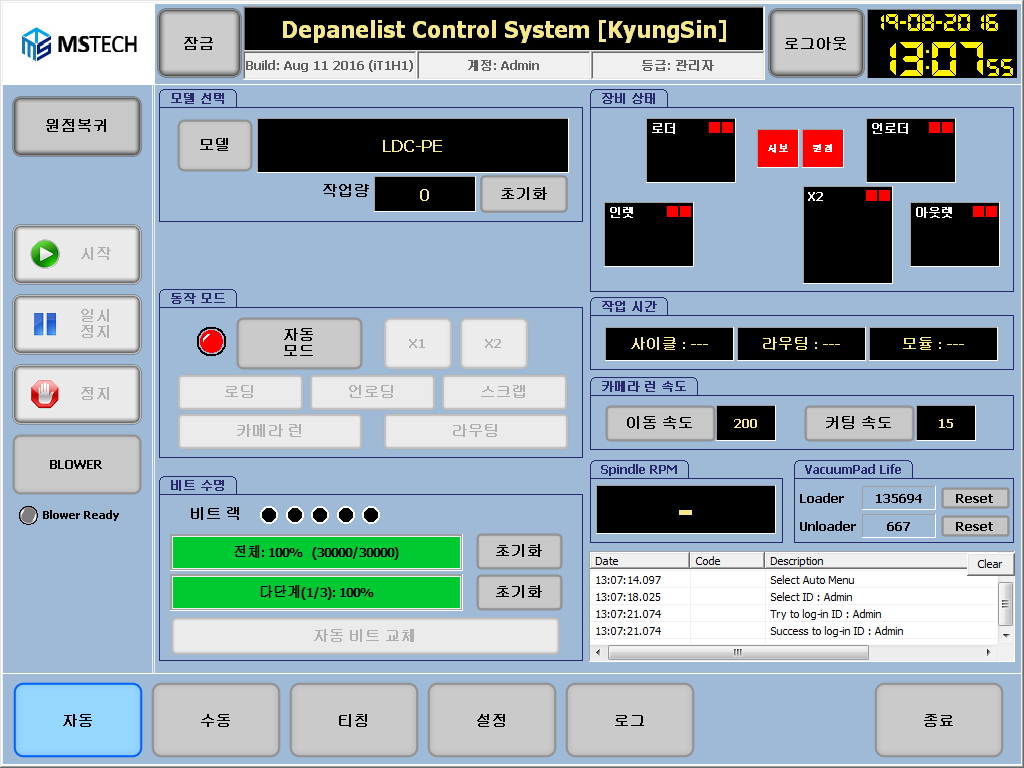

- Real-Time Monitoring of Spindle RPM

- Pass/Fail PCB Separation

- Independent Dual Z Axis

- Auto Load/Unload Position Teaching

- Dual Transfer for Minimum Idle time

- Compact Design

Options

- ID Verification with Fingerprint

- Barcode Interlock & MES

- AGV System Interlock

Features

-

- Auto Loading System(Tray)

- After cutting PCB, it is unloading it to tray directly and same direction by using rotated unloader after cutting it. And full try is released by order with stacking system.

-

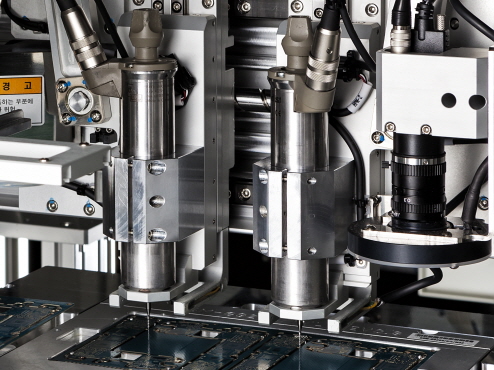

- Ultra High Speed Z Axis Up & Down

- It will be more improved cycle time & work capacity with developed & applied crank type z axis which is increased the up & down speed innovatively.

-

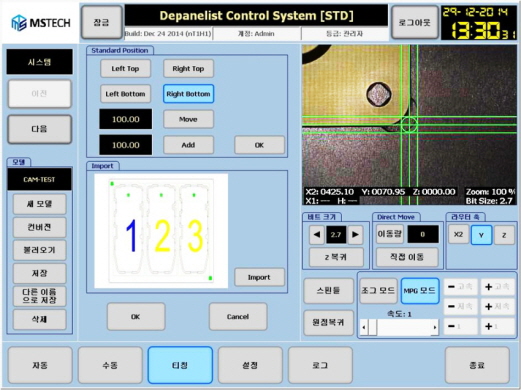

- Real-Time Monitoring of Spindle RPM

- It is protected PCB with sounding alarm when spindle PRM is declining by detecting it in real time.

-

- Pass/Fail PCB Separation

- It is separating and releasing the fail PCB by NG conveyor, after getting data of NG PCB from front equipment by MES.

-

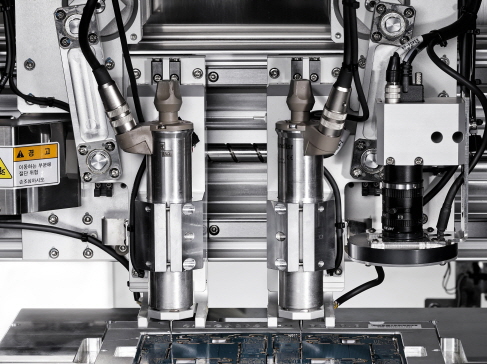

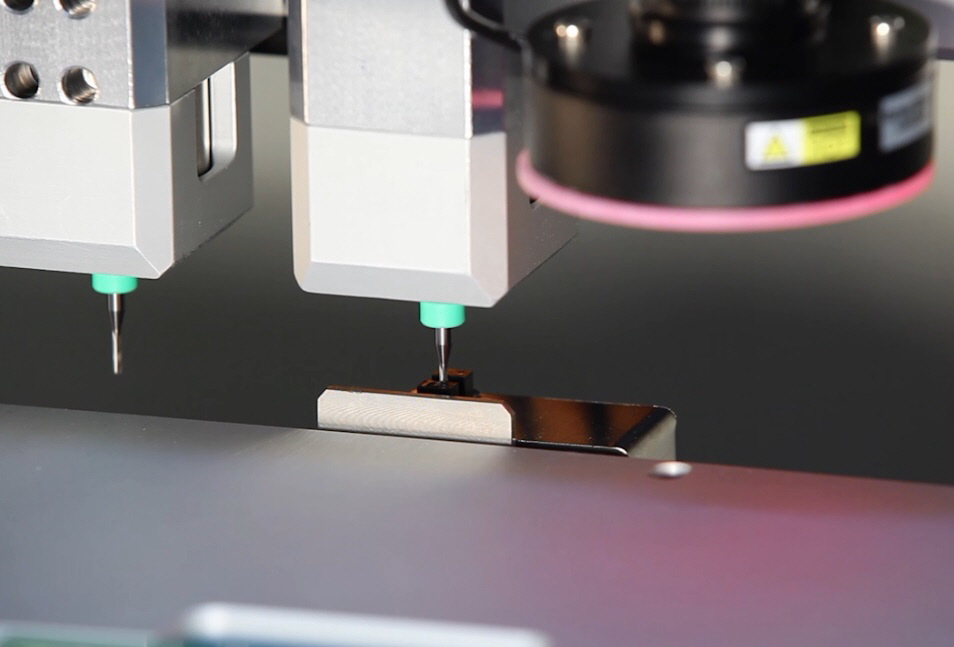

- Independent Dual Z Axis

- In during 2 heads cutting, if one PCB is left lastly, it is able to cut it by only one spindle.

-

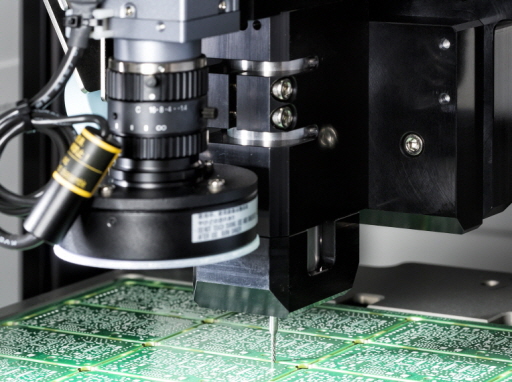

- Vision System

- It is able to detect different model and loading fail, and available fiducial checking.

-

- Wide Spindle Pitch

- Making more wider the spindle pitch than original 2 spindles, it is able to use cutting big size PCB.

-

- Auto Load/Unload Position Teaching

- It is shortened new model programing time innovatively with no need teaching the position of load/unload. Specially, it is able to be fest teaching the each unloading position with auto generating in the tray.

-

- Shuttle In-Let Conveyor

- PCB feeding position of in-let conveyor can be changed for response costumer's line layout

In-let flexibly.

-

- Auto Width Adjustment for Multi-Spindle(AWA)

- It is able to install 3~5 spindles in depending PCB array. Each spindle is able to do auto width adjustment(AWA)

(Patent)

-

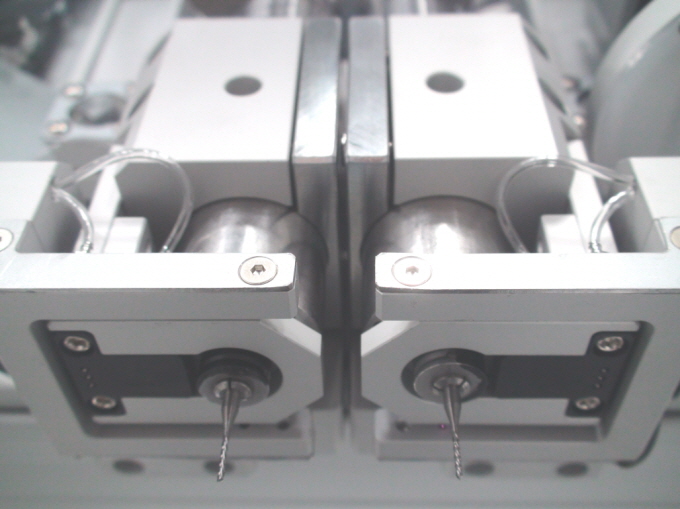

- Real-Time Bit Broken & Slip Down Detection

- It is sounded the alarm when bit broken & slip down with applied direct bit detection sensor type.

-

- Ionizer

- It is standard installation for protected PCB and efficient removing dust(area ionizing type)

-

- Dual Transfer

- It is applied the dual transfer which is load and unloader are working separately for minimum idle time.

-

- Compact Design

- It is the most compact design for securing customer space

-

- Loader / Unloader Rotating

- Loader/unloader are rotated 90 or 180 degree by model for fixing PCB on the jig or cutting area.

-

- Multi-Bit Function & Life Time Management

- It is using multi-bit by 2~3 level for reducing consumable cost of customer and sounding alarm when bit is on each level by life time management.

-

- UPS

- It is as Installed as Standard, and Protecting Data and Equipment From Line Shout Down.

(IPC Covering Capacity)

Options

-

- Barcode Interlock & MES

- It is used vision system or scanner to read the 1D/2D barcode for MES function with costumer's network

-

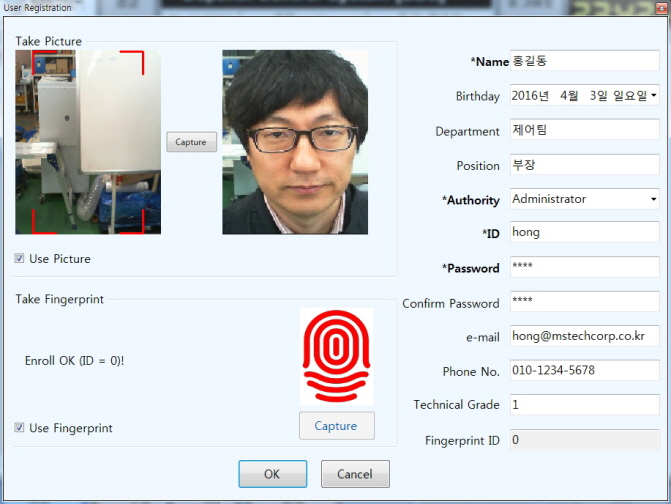

- ID Verification with Fingerprint

- It is available to be high security user management and easy logging by registered and appreciated user fingerprint.

-

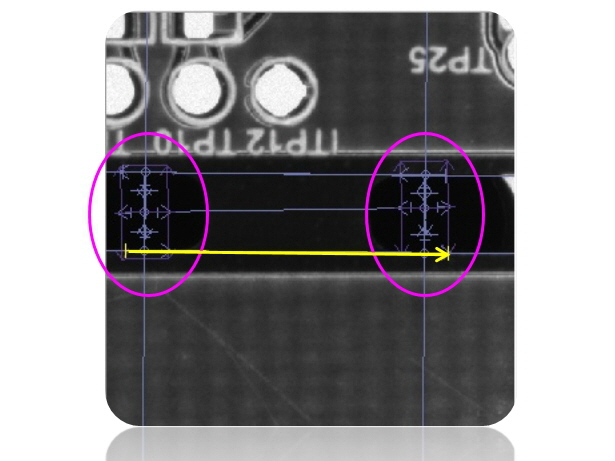

- Dimensional Inspection

- It is inspecting cutting measure & burr after cutting, and able to implement additional cutting.

-

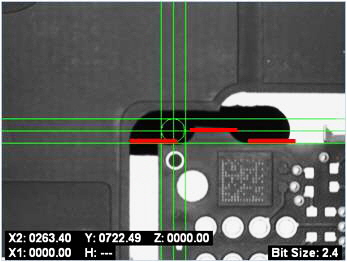

- Edge Detection Function

- As powerful vision system function, the both sides PCB edges beside a cutting tab are detected and compensate cutting position by tolerance of boards.

-

- CAD/CAM Data Conversion

- It is converted CAD/CAM data to routing cutting data then able to do offline programing.

-

- AGV System Interlock

- It is software module for auto loading/unloading the tray stack with connecting customer’s AGV system.

-

- Gripper Unloader

- If there is restriction of unloading with heavy PCB or high component, it is able to use gripper type of unloader.

-

- Visual Data Log System (Visual Recorder)

- It is able to check phenomenon & cause by video recoding & saving inside of equipment when issue is happened during it is working.

-

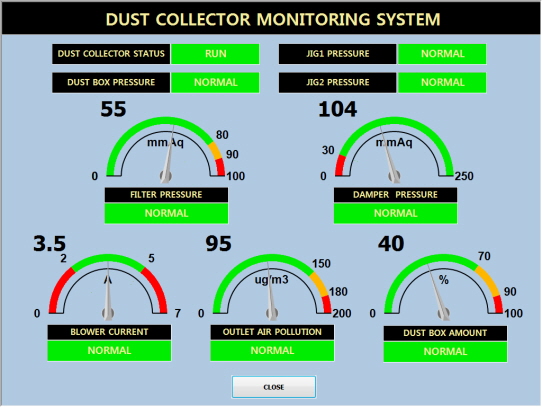

- Real-Time Self-Diagnosis Dust Collector

- It is able to do self-diagnosis about pressure, damage & pollution level inside dust collector and sound alarm to router(patent-pending)

-

- Filter+Cyclone Complex Dust Collector

- It is able to use filter semi-permanently with applied cyclone, and install plastic bag.

-

- Easy Handling Dust Collector

- It is able to use the plastic bag for disposing dust cleanly & easily.

Specifications(Standard)

Layout

Video