MSTECH

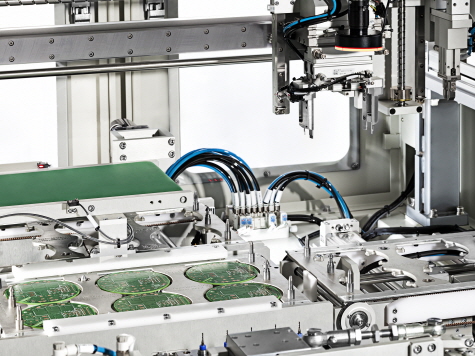

Home Products > PCB Depaneling Router

Product

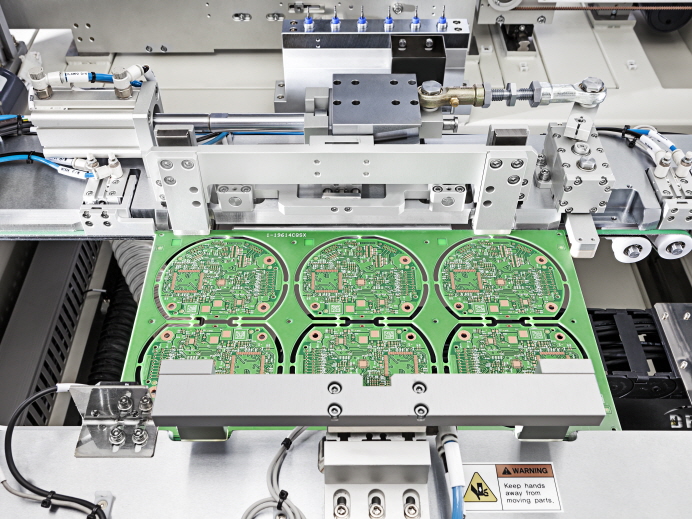

iDPL-U (Undercut) Undercut In-Line Router

Features

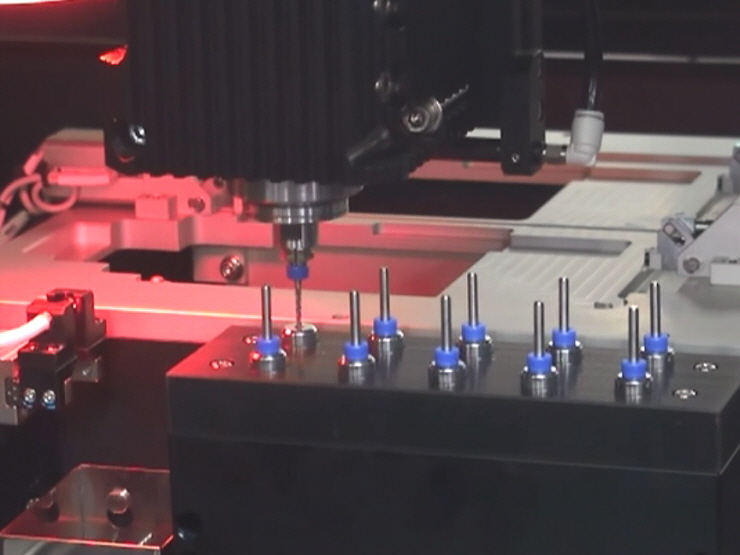

- Bottom Cutting Router

- Jig – Less with Gripper Type

- High Efficiency Dust Collecting System for 0% Remaining Dust

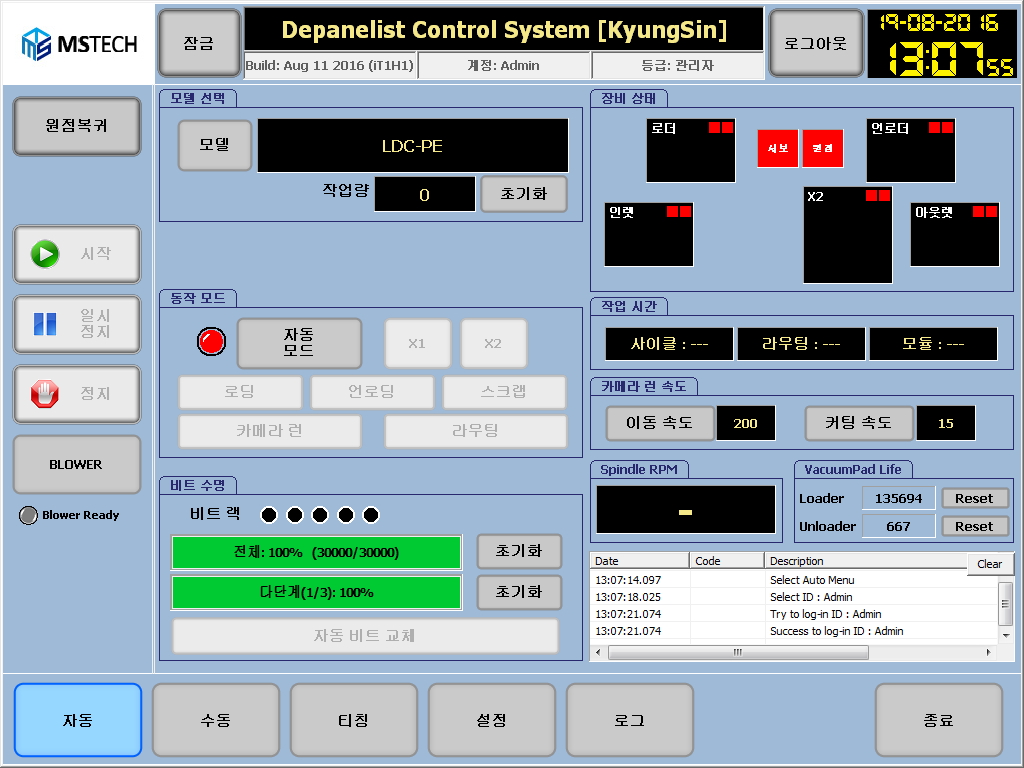

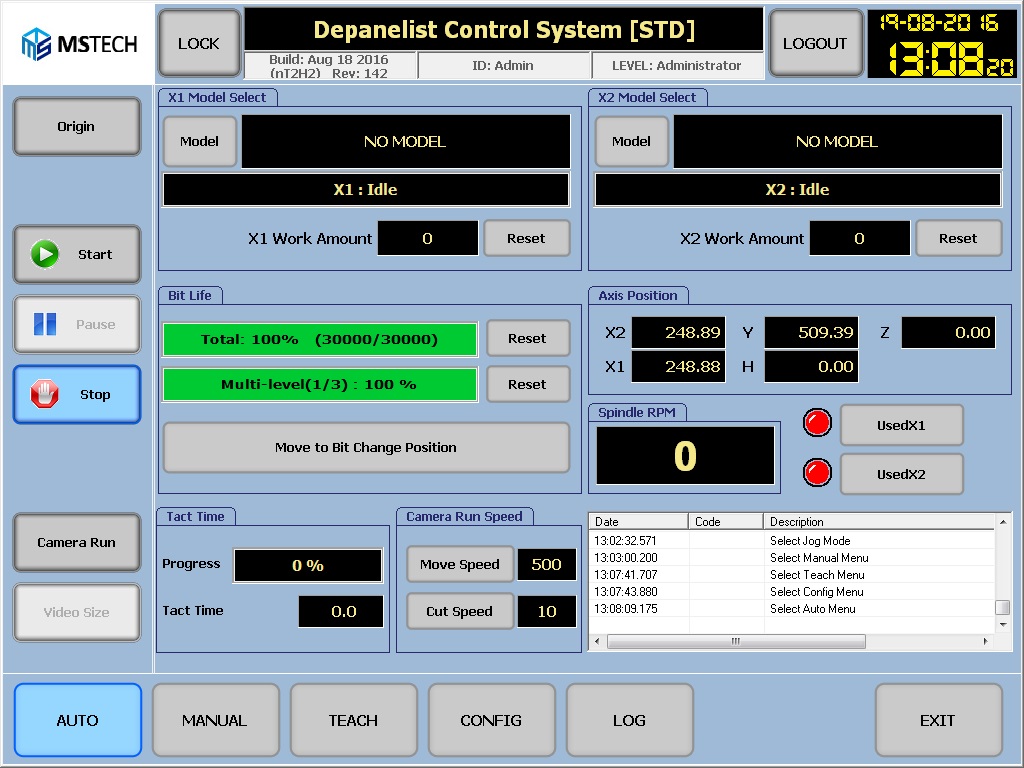

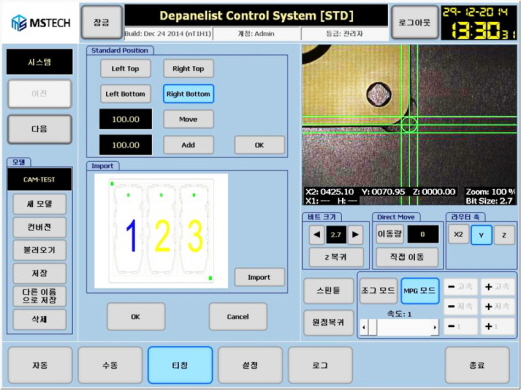

- User Friendly GUI based on IPC& Touch LCD

- Compact Design

Options

- Barcode Interlock & MES Interface

- Pallet Transferring System

- OK/NG PCB Separation

- ID Verification with Fingerprint

Features

-

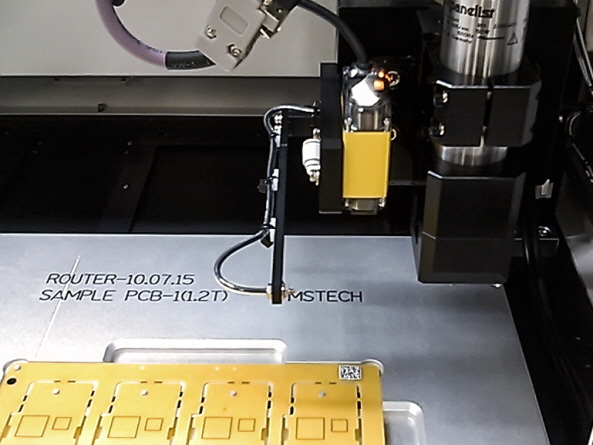

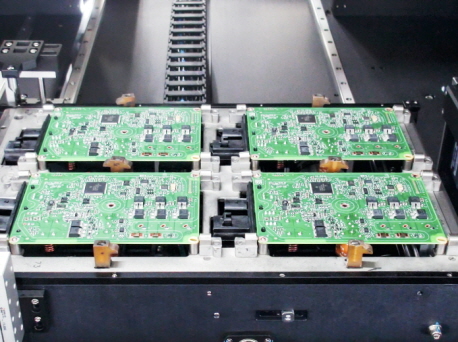

- Jig-Less

- It is used the gripper for PCB gripping, so no need to produce jig by model. And cutting PCB on the conveyor with 3~4 grip fingers grip it stably.

-

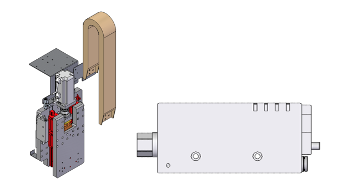

- Bottom Cutting Router

- PCB is gripped by upper and cutting by bottom, it is free for component high on the PCB.

-

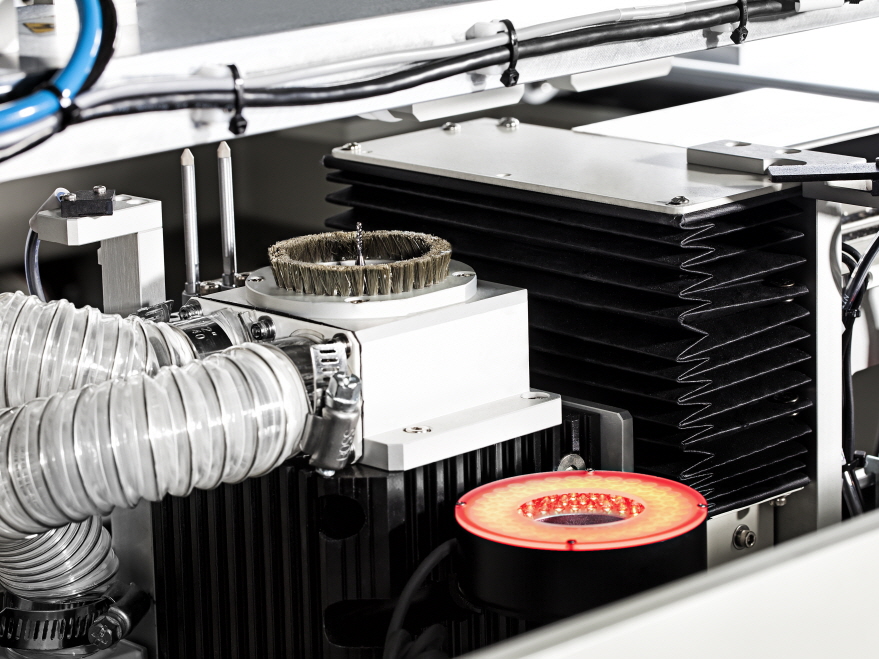

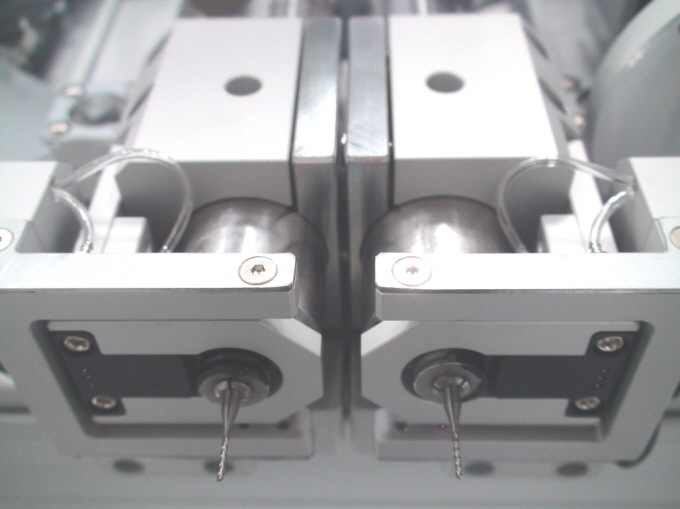

- High Capacity 500W Spindle

- It is cutting PCB stably with strong power as 500W spindle motor which is made in Germany.

-

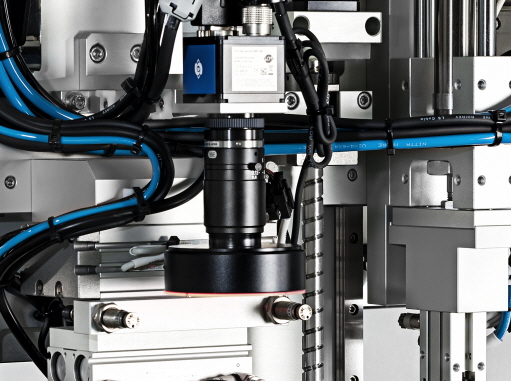

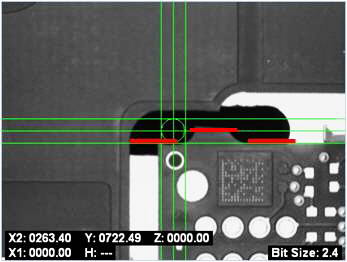

- Vision System

- Vision system is standard installation for camera teaching and able to revise data after fiducial check.

-

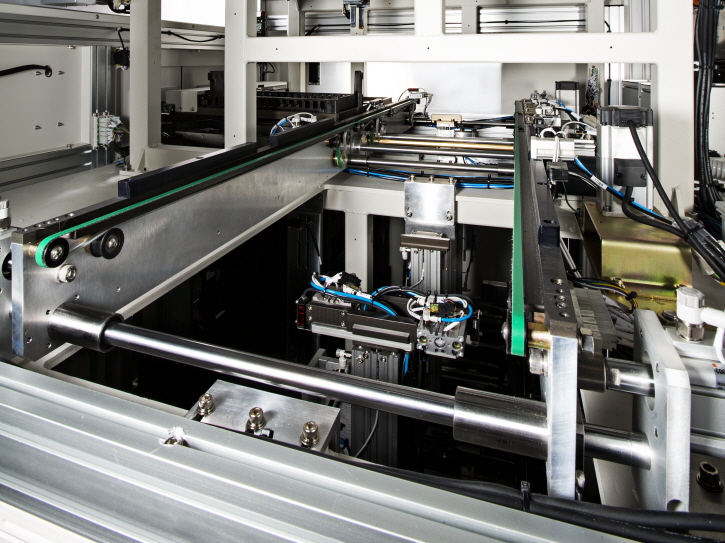

- Auto Conveyer Width Adjustment

- It is saved model changing time by using motor to save the parameters of width pitch.

-

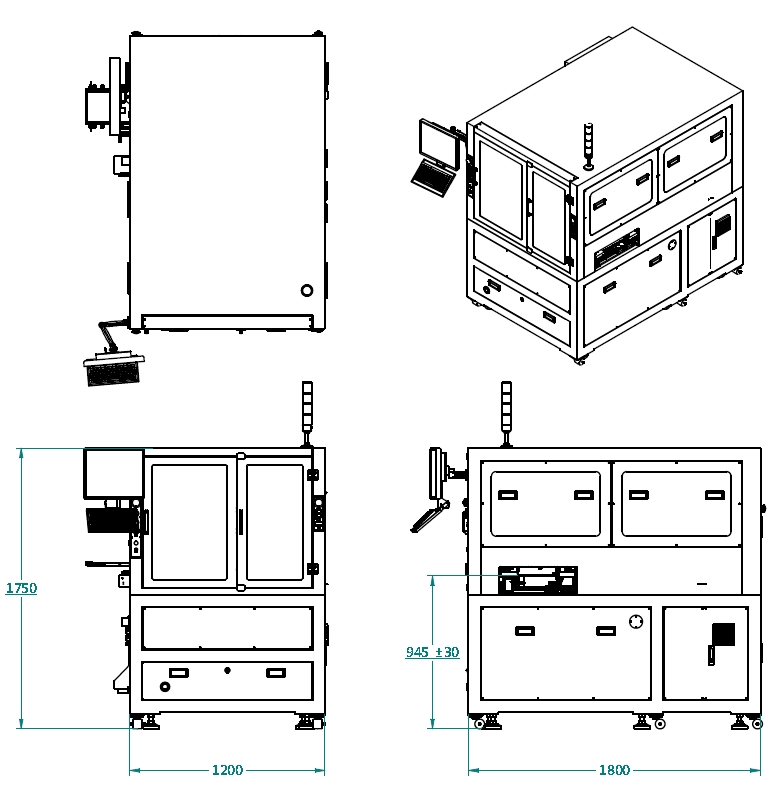

- Compact Design

- It is the most compact design for securing customer space.

-

- Bit Broken & Slip Down Detection

- Bit detection sensor is standard installation for sounded alarm when bit broken & slip down.

-

- Multi-Bit Function & Life Time Management

- It is using multi-bit by 2~3 level for reducing consumable cost of customer and sounding alarm when bit is on each level by life time management.

-

- Ionizer

- It is standard installation for protected PCB and efficient removing dust(area ionizing type)

-

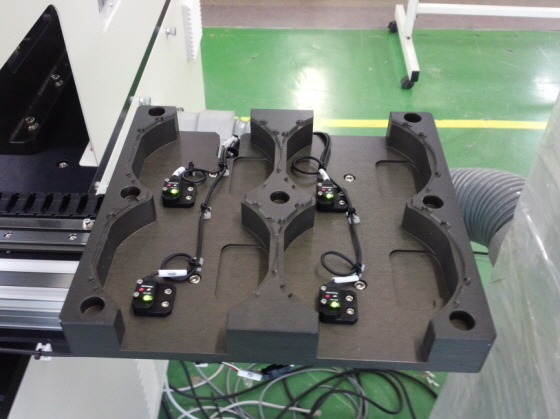

- Gripper Rotating

- Gripper is able to rotate 90 or 180 degree. For unloading, it is able to rotate in depending PCB fixing and releasing way by model.

-

- Easy & Convenient S/W

- It is for high visibility and able to make & operate program easy & operating by applied full graphic user interface.

Options

-

- Barcode Interlock & MES

- It is used vision system or scanner to read the 1D/2D barcode for MES function with costumer's network.

-

- Pass/Fail PCB Separation

- It is separating and releasing the fail PCB by ng conveyer, after getting data of NG PCB from front equipment by MES.

-

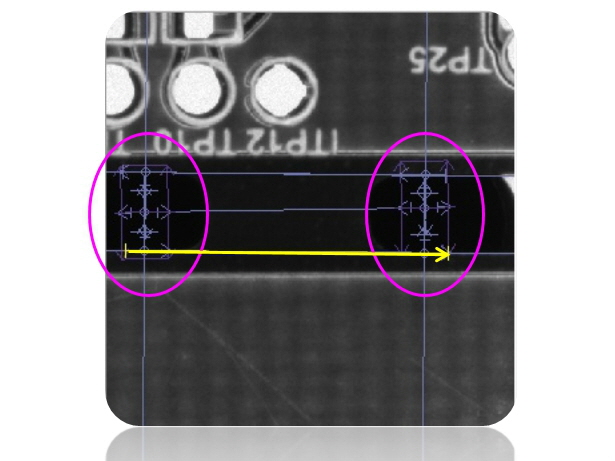

- Edge Detection Function

- As powerful vision system function, the both sides PCB edges beside a cutting tab are detected and compensate cutting position by tolerance of boards.

-

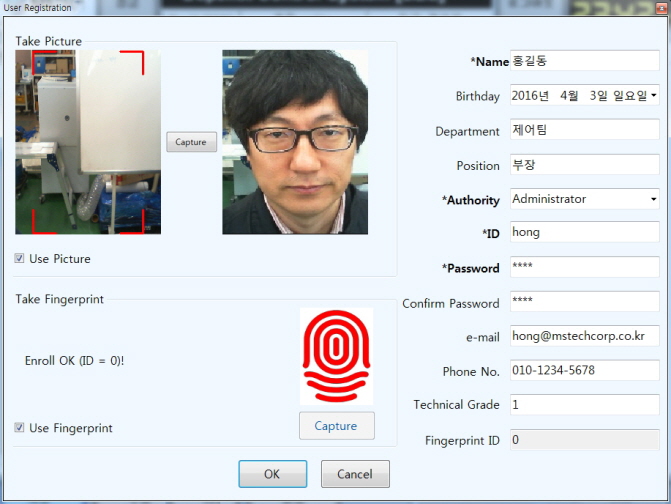

- ID Verification with Fingerprint

- It is available to be high security user management and easy logging by registered and appreciated user fingerprint.

-

- Dimensional Inspection

- It is inspecting cutting measure & burr after cutting, and able to implement additional cutting.

-

- CAD/CAM Data Conversion

- It is converted CAD/CAM data to routing cutting data then able to do offline programing.

-

- Real-Time Spindle RPM Monitoring

- It is protected PCB with sounding alarm when spindle PRM is declining by detecting it in real time.

-

- Auto Tray Function

- It is loaded PCB after cutting it to tray or slot box by automatically, also auto changing and stacking tray or slot box when PCB is full in there.

-

- Pallet Transporting System

- After cutting PCB, it is released seated on the pallet from costumer.

-

- Shuttle Jig Outlet

- It is releasing PCB by seated on the shuttle jig for automation of next equipment.

-

- Auto Tool Changing System(ATC)

- When life of bit is almost done or it is broken, it is changed the bit automatically. (Available with 4033 and 4041 spindle only)

-

- Visual Data Log System (Visual Recorder)

- It is able to check phenomenon & cause by video recoding & saving inside of equipment when issue is happened during it is working.

-

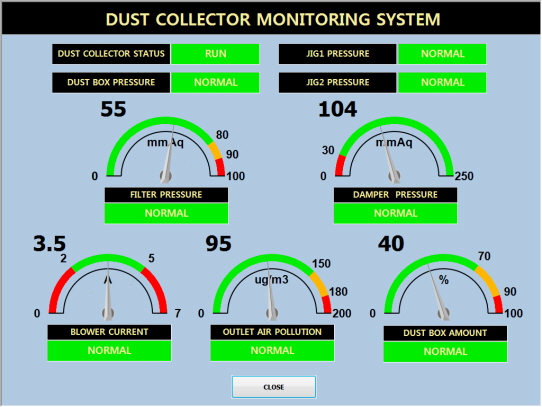

- Real-Time Self-Diagnosis Dust Collector

- It is able to do self-diagnosis about pressure, damage & pollution level inside dust collector and sound alarm to router(patent-pending)

-

- Filter+Cyclone Complex Dust Collector

- It is able to use filter semi-permanently with applied cyclone, and install plastic bag.

-

- Easy Handling Dust Collector

- It is able to use the plastic bag for disposing dust cleanly & easily.

Specifications(Standard)

Layout

Video