MSTECH

Home Products > PCB Depaneling Router

Product

nDPL-S (Single) Single Off-Line Router

Features

- Single Table Off-Line Router

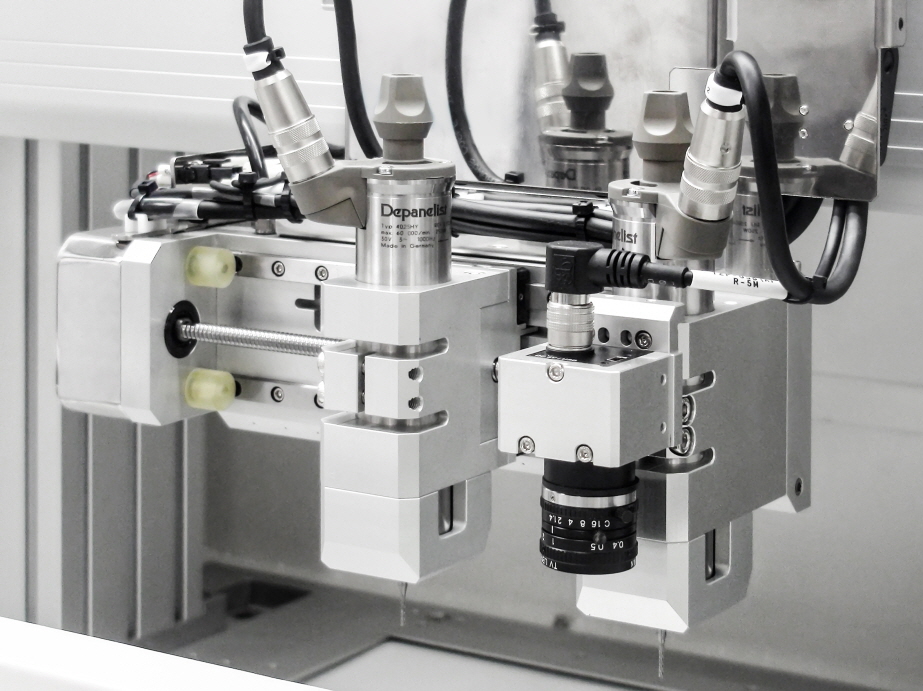

- Dual Spindle as Standard

- High Efficiency Dust Collecting System for 0% Remaining Dust

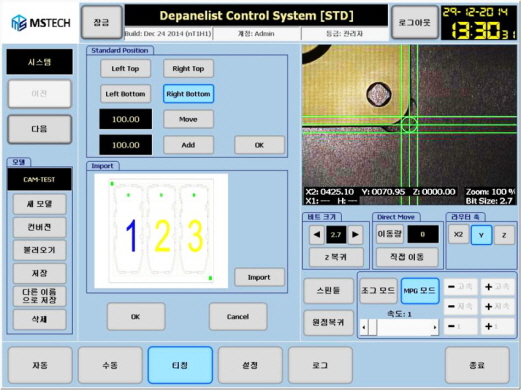

- Quick & Easy Programming with Camera & MPG/Jog

- User Friendly GUI Based on IPC & Touch LCD

- Compact Design

Options

- Vision System

- Barcode Interlock & MES Interface

- Bit Detection System

- ID Verification with Fingerprint

Features

-

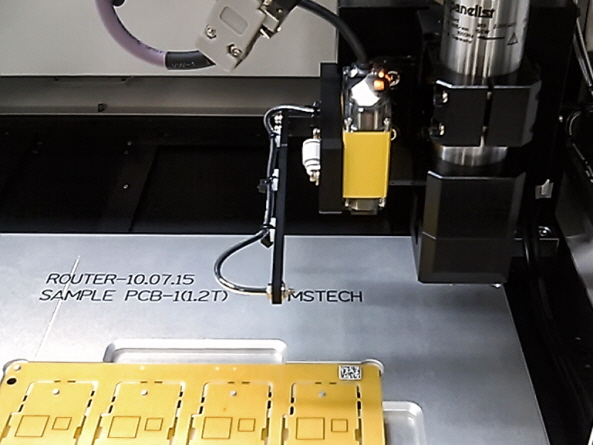

- Single Shuttle Table

- It is able to respond flexibly at production line with applied single table. (Lean concept)

-

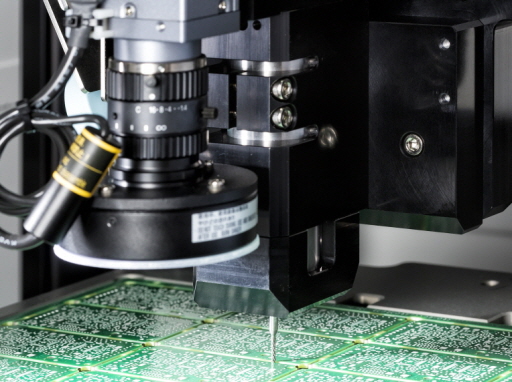

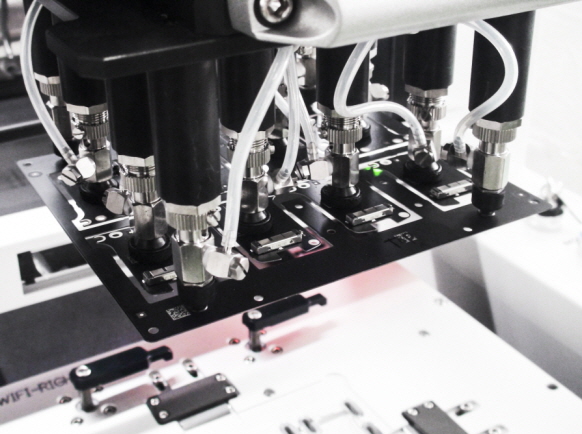

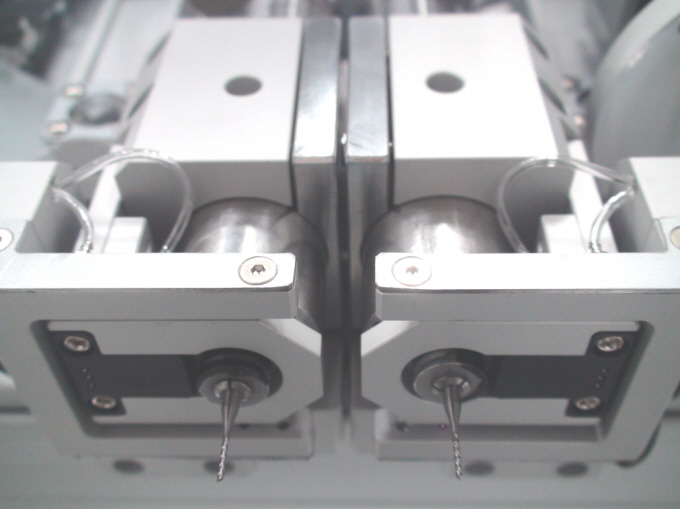

- Dual Spindle Head

- It is able to be fast cutting speed & high performance by applied 2 spindle head as standard. And do auto adjustment spindle width by model. (Option, up to 3~4 spindles)

-

- Operator Reduction

- It is reduced the operator & management expense to apply multi head as efficacy of 2 machines.

-

- Camera Teaching

- It is available teaching accurately & easily to use camera

-

- Compact Design

- It is the most compact design for securing customer space

-

- Multi-Bit Function & Life Time Management

- It is using multi-bit by 2~3 level for reducing consumable cost of customer and sounding alarm when bit is on each level by life time management.

-

- Ionizer

- It is standard installation for protected PCB and efficient removing dust(area ionizing type)

-

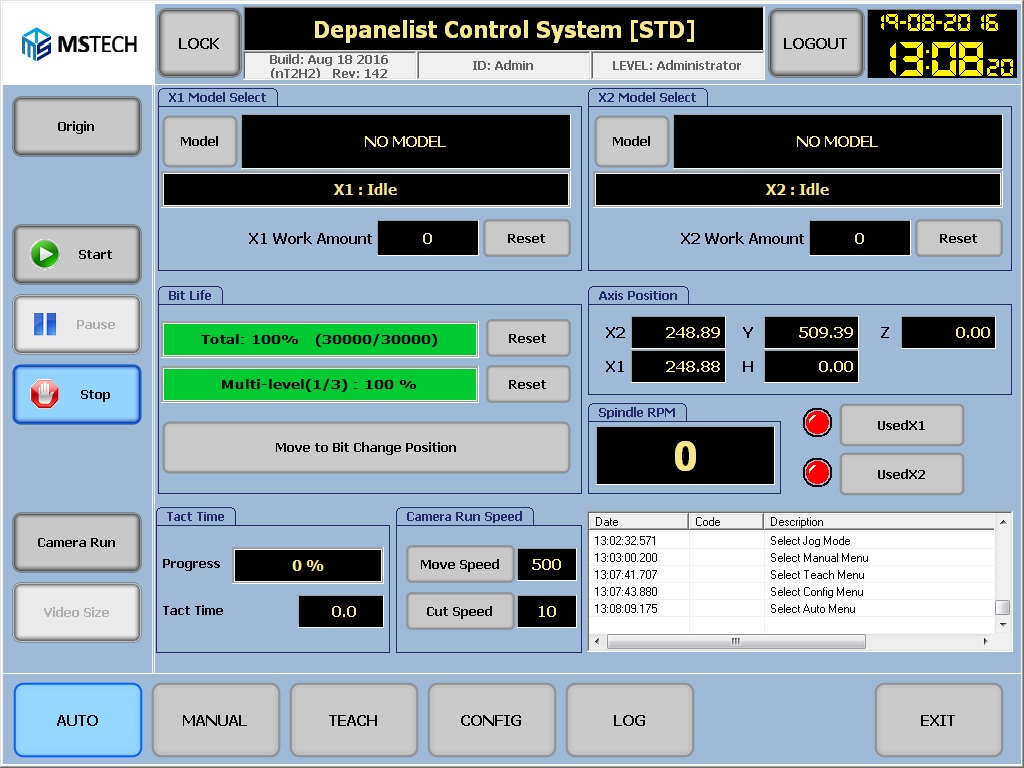

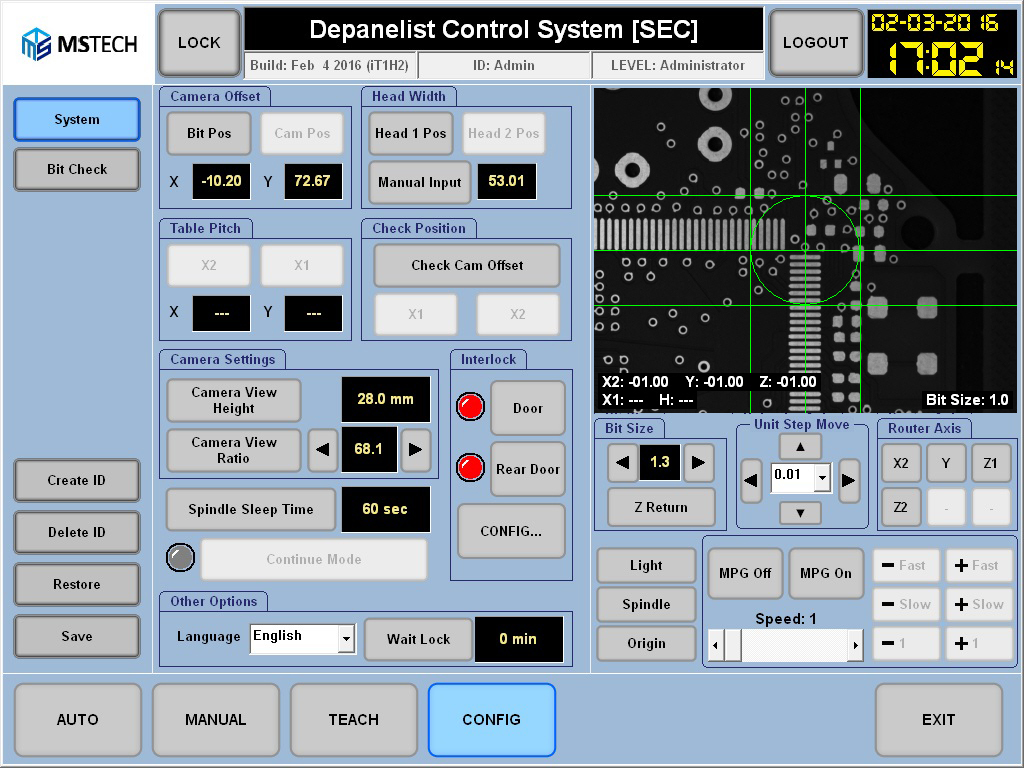

- Full Graphic Interface

- It is easy & comfortable operation by applied GUI base on windows

-

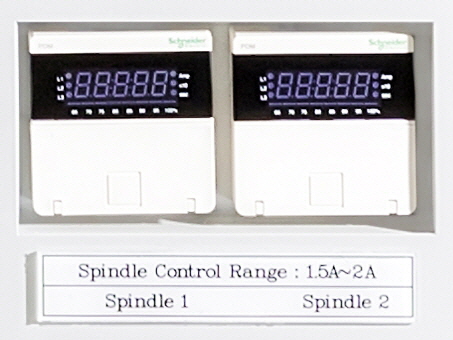

- Spindle Mate(Self-diagnosis)

- It is prevented the PCB damage caused by spindle with detecting the spindle status by real-time.

-

- Safety Sensor

- It is applied for safety of operator of loading/unloading PCB.

Options

-

- Vision System

- It is able to detect different model and loading fail, and available fiducial checking.

-

- Barcode Interlock & MES

- It is used vision system or scanner to read the 1D/2D barcode for MES function with costumer's network

-

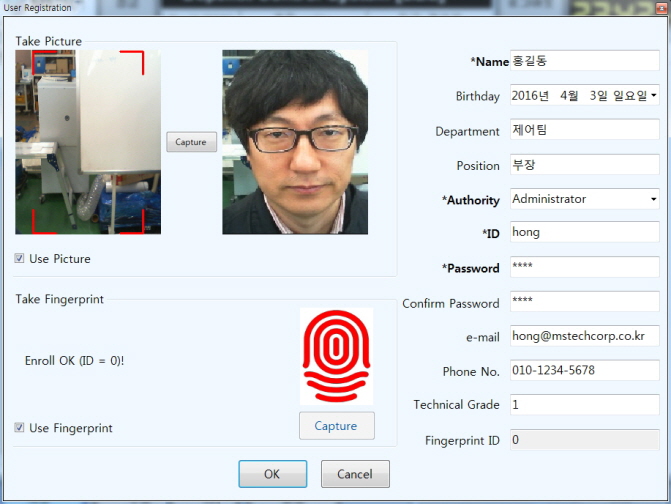

- ID Verification with Fingerprint

- It is available to be high security user management and easy logging by registered and appreciated user fingerprint.

-

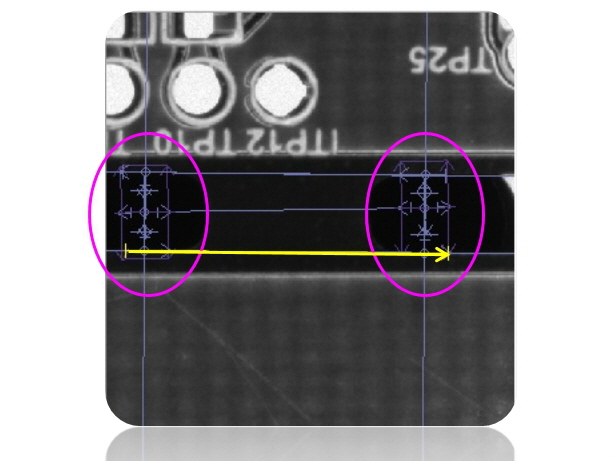

- Edge Detection Function

- As powerful vision system function, the both sides PCB edges beside a cutting tab are detected and compensate cutting position by tolerance of boards.

-

- PCB Unloader

- It is using the vacuum type unloader to pick PCB up from jig for avoiding operator mistakes unloading PCB.

-

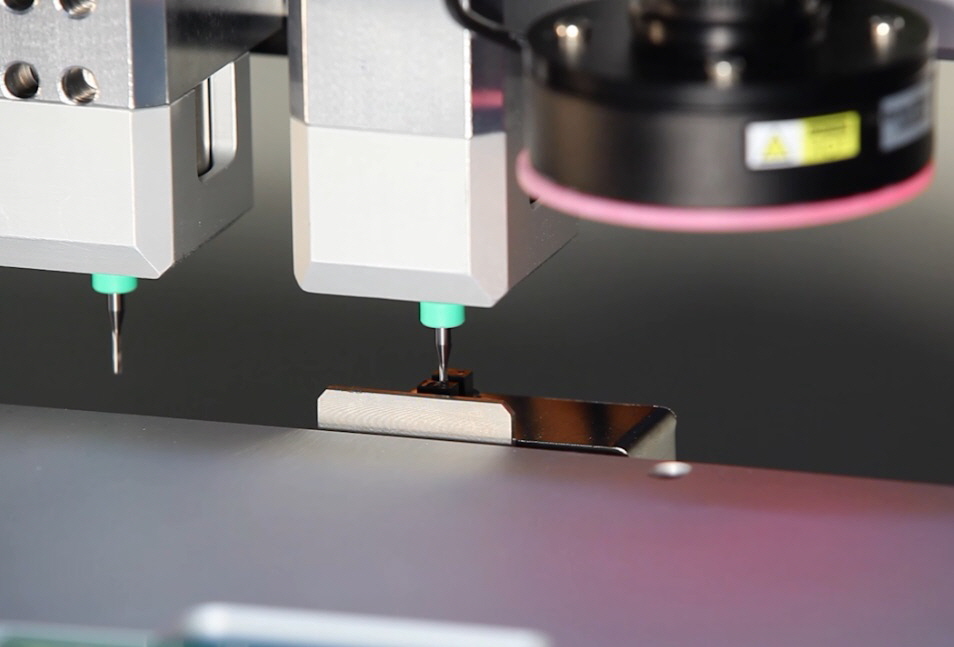

- Bit Detection Sensor

- It sounds the alarm when detecting bit broken automatically

-

- CAD/CAM Data Conversion

- It is converted CAD/CAM data to routing cutting data then able to do offline programing.

-

- Real-Time Spindle RPM Monitoring

- It is protected PCB with sounding alarm when spindle PRM is declining by detecting it in real time.

-

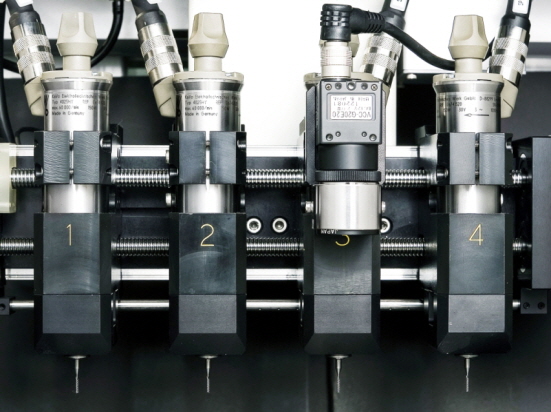

- Auto Width Adjustment for Multi-Spindle(AWA)

- It is able to install 3~5 spindles in depending PCB array. each spindle is able to do auto width adjustment(AWA)

(patent)

-

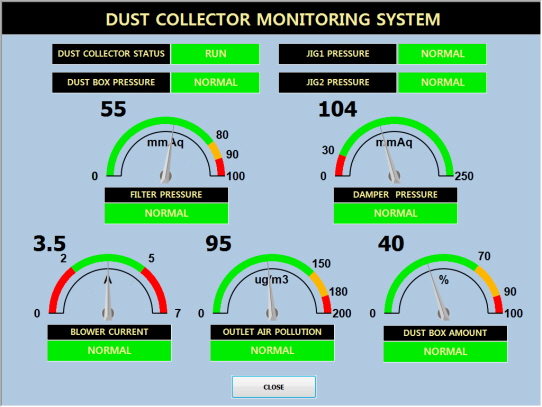

- Real-Time Self-Diagnosis Dust Collector

- It is able to Do Self-Diagnosis about Pressure, Damage & Pollution Level Inside Dust Collector and Sound Alarm to Router(Patent-Pending)

-

- Filter+Cyclone Complex Dust Collector

- It is able to use Filter Semi-permanently with Applied Cyclone, and Install Plastic Bag.

-

- Easy Handling Dust Collector

- It is Able to Use The Plastic Bag for Disposing Dust Cleanly & Easily.

Specifications(Standard)

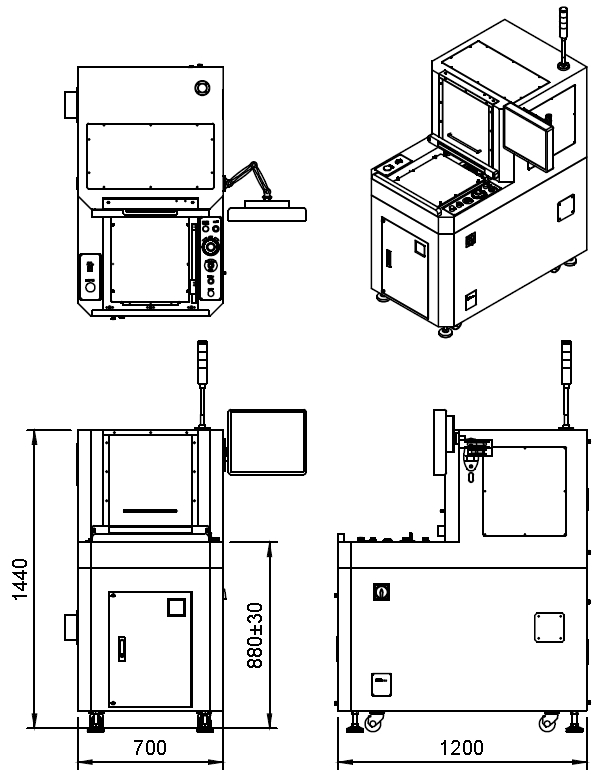

Layout